Building Smarter with Hollow Blocks: The Modern Masonry Solution

Introduction

In the evolving world of construction, the demand for materials that are strong, cost-effective, and sustainable has never been greater. One material that perfectly balances all three is the hollow block. Among the different types available, non-load bearing hollow blocks stand out as an especially efficient and design-savvy solution for modern structures. Whether you’re developing residential spaces, commercial interiors, or industrial-style builds, these blocks offer more than just structure—they offer style.

What Are Non-Load Bearing Hollow Blocks?

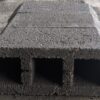

Non-load bearing hollow blocks are precast concrete masonry units designed primarily for partition walls and enclosures that do not support structural loads. These blocks typically have large hollow cores to reduce weight and material usage, making them ideal for internal walls and architectural applications.

Key Features:

- Lightweight and easy to handle

- Available in various sizes and finishes

- Provide an attractive, industrial look when left exposed

Where Are They Used?

Non-load bearing hollow blocks are incredibly versatile and commonly used in:

- Internal partitions

- Office and residential fit-outs

- Boundary walls (non-structural)

- Decorative facades and enclosures

Why Use Non-Load Bearing Hollow Blocks?

- Fast and Cost-Efficient Construction: Their larger size and lightweight nature speed up the building process, reducing labor and mortar requirements.

- Finish Savings: These blocks offer versatility in finishes. They can be left exposed to achieve a modern, industrial look, thus removing or reducing the need for plaster, paint, or cladding. Alternatively, due to their consistent thickness, they may only require a thin plaster finish.

- Thermal and Acoustic Insulation: The presence of hollow cores within the building’s structure creates a natural thermal barrier. This occurs because air trapped within these cavities acts as an insulator, slowing the transfer of heat between the interior and exterior environments. As a result, the building’s internal temperature remains more stable, reducing the need for artificial heating or cooling. This enhanced thermal performance not only improves occupant comfort but also contributes to lower energy consumption and reduced utility costs.

- Eco-Friendly: Hollow blocks are an eco-friendly building material because their hollow design reduces concrete needed in production, thus conserving resources and lowering environmental impact. As precast elements, they minimize on-site waste compared to traditional bricklaying. The reduced concrete usage also translates to lower greenhouse gas emissions, promoting greener building practices..

Why Choose Our Hollow Blocks?

At Kwangu Kwako, we specialize in high-quality non-load bearing hollow blocks engineered for durability, efficiency, and design. Here’s what makes our products the best choice for your project:

- Aesthetic Versatility: Clean, consistent finish ideal for exposed applications

- Dimensional Accuracy: Perfectly shaped for seamless installation

- Sustainable Manufacturing: Produced with eco-conscious methods and materials

- Expert Guidance: From design advice to delivery logistics, we support your build from start to finish

Build with Purpose and Style

If you’re seeking a practical, stylish, and sustainable solution for internal or decorative walls, our non-load bearing hollow blocks are your ideal choice. Experience modern construction without the extra layers of finishing.

Contact us at 0705868826 or Email, or Request a quote to consult with one of our experts.

Build faster. Build smarter. Build with hollow blocks from Kwangu Kwako.